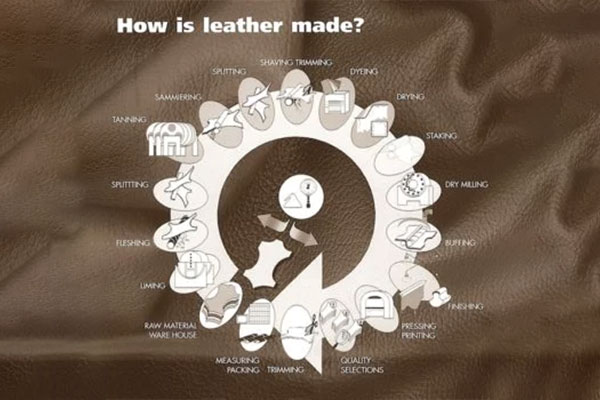

How is leather made? Is a question a lot of people are often wondering about. The global leather goods market will reach $121 Billion by 2022, out of which 90% will be held by retail stores and outlets.

It’s safe to say that the fashion world would be incomplete without the leather and products made from it, especially without leather jackets, handbags, and shoes. This post is specifically written to explain the in-depth process of making leather to leather enthusiasts and others seeking info about how leather is made.

The art of making leather goes as far back as the dark ages, if not before; when ancient people discovered animal hides and skins that were at the time, naturally tanned using decaying plant material.

Eventually, they discovered, how leather is made; a better version of wearable animal hide. This was done by removing the hair of the animal, using stone tools, and applying a solution that comprised of animal fat, wood smoke, or the tan-rich juices of plants to preserve the hide.

This was one of the first techniques that were set in motion and that gave rise to many other treatments of leather processing that spread like wildfire.

In this article, we’ll be touching on the following key points to have a good understanding of how leather is made:

What To Expect In This Article?

Some History of Leather

If ancient paintings and artifacts are anything to go by, animal hides and skins were worn from the Paleolithic period to ancient Egypt, Rome, and many such civilizations that helped in modifying this art form and transforming it into what it is today.

Hides and skins of various animals such as cowhide, buffalo, sheepskin, goatskin, etc. that can be made into leather products such as apparel, footwear, bags, accessories, even personalized products, furniture, objects, and more, highlight the wonder of an evolutionary process that the people of today can enjoy the most.

The Science Behind Leather

For starters, there are different types of leather and it is described as the hide and skin of an animal, complete with its original fibrous structure, intact in an ideal situation. With or without hair or wool, it is tanned to safeguard it against decomposition.

As mentioned before, hide covers large animals such as cows and buffalo in certain cases where horse hide is also used. Skins cover a range of smaller animals such as sheep, goats, and deer, and in some countries kangaroos to ostriches, snakes, and yes even alligators.

Interestingly, an animal’s skin comprises protein collagen, the chemistry of which covers a fibrous protein that serves as one of the components of the skin’s biological makeup. This point is of great interest to the tanner as it affects the final appearance of the leather product.

Beam House Operations

All the stages of the making of leather between curing and tanning are collectively known as beam house operations. This area includes soaking, liming, and removal of extraneous tissues (fleshing, hair removal, and scudding) deliming, bating, drenching, and pickling.

Soaking

Hides and skins are soaked in clean water to remove the salt that may be left over from curing and to increase the moisture so that the hide or skin can be treated further. To prevent hide or skin damage by any kind of bacteria during the soaking period, biocides may be used.

Fungicides such as 2-thiocyanomethylthiobenzothiazole may be added later in the process, to protect wet or damp leathers from mold growth. Post 1980, it is forbidden to use pentachlorophenol and mercury-based biocides and their derivatives.

Liming

After soaking, the hides or skins are taken for liming which is a milk and lime treatment that may involve the addition of sharpening agents such as sodium, sulfide, amines, cyanides, etc. The basic objective of this portion of the process is to remove hair.

Some of the interfibrillar soluble proteins such as mucins are used to swell up and split up the fibers to the desired extent, to remove natural grease and fats to a great extent, and to bring collagen in the hide or skin to a proper condition for satisfactory tanning.

The breakdown of the disulfide link of the amino acid cysteine which is the characteristic of the keratin class of proteins that gives strength to hair is actually what determines the weakening of hair and even wool.

The hydrogen atoms supplied by the sharpening agent weaken the cysteine molecular link whereby the covalent disulfide bond links are eventually ruptured, thus weakening the keratin.

To a certain extent, sharpening also contributes to hair removal as it tends to break down hair proteins in their entirety.

Scudding and Unhairing

The removal of hair or wool from hides or skins is referred to as Unhairing in this context. Unhairing agents such as sodium hydroxide, sodium sulfide, or calcium hydrosulfide are used.

The remaining hair is removed mechanically, initially through a machine and then by hand using a dull knife. This in particular is known as scudding.

Bating and Deliming

This is where the pH (potential of Hydrogen) is brought down to the lowest level so that the enzymes may act on it. This is called Deliming.

Depending on the end-use of the leather, hides and skins may be treated with enzymes to soften them so they are pliable enough to work on. This is referred to as Bating.

Modern tanning enables a step to be skipped where bacterial fermentation, achieved through dung-water soaking is no longer required.

Pickling

The stage after Bating and Deliming sees the hides and skins being treated first with salt and then with sulfuric acid, should mineral tanning is to be carried out.

This is achieved by bringing down the pH of collagen to a very low level, which results in the facilitation of the penetration of mineral tanning agents into the substance. This process is what is referred to as Pickling.

The common salt or sodium chloride penetrates the hides or skins twice as fast as the acid and checks the ill effect of the sudden drop of pH.

How is Leather Made?

Since leather is sold by area, it is important to have the perfect measurements of the item you will be making with the hides or skins. So accuracy is key. Below we cover the different stages of the process of how is leather made:

Prepping the Hides or Skins

First off, hides and skins need to be prepped. This involves the removal of the skin or hide from the flesh of the animal. The animal is skinned by setting it on its back, in an inclined position.

Using a good hunting knife for skinning is important. After the removal of sex organs, the animal is sliced from tail to throat after which the skin is peeled back with the fingers or knife.

After splitting the sternum, the rib cage and other organ removal are carried out. The animal is then flipped over and the removal of hide or skin is completed.

Most manufacturers use an alternative to this method by using a mechanical fleshing machine to remove the flesh from the inside of the skin or hide. Running the inside of the skin or hide over a steel roller machine will eliminate or lessen the inclusion of excess flesh.

If a fleshing machine is not accessible, purchasing fleshing tools from a hunting store or taxidermy supply store would be a good option.

Next, the flesh is draped over a large horizontal beam where a small section of the hide or skin is pinned to the end of the beam. If a beam is unavailable, the hide or skin can simply be spread on a tarp on the floor.

It is important to note that a large basin or bucket, placed below your work area to catch any excess tissue or fats as they are scraped away is a good idea. The hide or skin is then rotated until the surface is complete.

Any form of breaks should be avoided, as this can cause the material to dry out. After fleshing, the end result should be a smooth, white surface.

Salt the Skin

A generous layer of salt is applied to the skin or hide that acts as a preservative to keep the material from decomposing. Fresh skins or hides need to be salted or frozen within the first few hours or they may get destroyed.

Next, the material is folded in half so that the flesh sides are together and leaving it for twenty-four hours approximately, any residue or remaining salt that is found is scraped away and this step is repeated.

Soaking the Hide or Skin

This stage helps in removing any dirt or other materials from the hide or skin. In a large 35-gallon or so container, with fresh cool water, the skin or hide is placed for at least a day. The longer you let it soak, the easier it may make the hair removal process.

Hair Removal from the Skin

This can be accomplished chemically with a solution or calcium oxide AKA slated lime, whitewash, or calcium hydroxide. The same tools for unhairing that were used for fleshing can also be used. After the hair is removed the skin or hide may be hung to dry.

A Final Bath

Adding a teaspoon of calcium hydroxide per gallon of water, to create lime water, a final bath is given to the hide or skin to remove any inter-fiber substances or unnecessary proteins.

It will also help to soften the skin and loosen any remaining hair follicles. After removing the material from the lime bath, a final rinse is given to thoroughly clean the surface.

Deciding On a Tanning Process

Speaking of tanners, let’s go through the tanning system of leather that is linked to the overall process of how leather is made. First off, hides and skins are sent to a tannery which is the place where tanning (a process of treating hides and skins of animals to produce leather) is carried out.

Tanning hide into leather involves, for the most part, a process that permanently alters the protein structure of hide or skin as mentioned above, making it durable and less if not totally unlikely of decomposition. Also, in some cases giving it another color.

Prior to tanning, the hides or skins go through hair removal, degreased, desalted, and soaked in water for anytime between six hours to two days.

Glancing through history, we are told that this process of tanning used tannin, which is an acidic chemical compound from which the tanning process draws its name.

Tannin is a German word that means oak or fir trees from which the compound was drawn. On arrival of the Industrial Revolution, a type of Chromium which is another solution was adopted by tanners.

The tanning process begins with obtaining hides or skins preferably leaving out the actual killing of animals solely for this purpose. These hides or skins go through curing to prevent decomposition of the protein substance called collagen from bacterial growth.

Curing removes the water from the hides or skins, using a difference in osmotic pressure. With the increase of osmotic pressure comes the decrease of moisture content which ensures the inability of bacteria to grow. In ‘wet-salting’, the hides or skins are salted and then pressed into packs for approximately a month.

However, ‘brine curing’ enables the hides or skins to be agitated in a bath of saltwater for around sixteen hours. Still another mode of curing can be accomplished by preserving the hides or skins at very low temperatures.

Depending on which method you choose, this process can take anywhere between one to four days. After this, the leather is cut, based on the user’s requirements. The following are the types of tanning used in connection with how to make leather.

Vegetable Tanning

This makes use of tannin extract which occurs naturally in a variety of different tree barks such as oak, chestnut, tanoak, or hemlock. The tannin extract is mixed with water and placed in a rotating drum along with animal skin or hide.

The rotation of the drum will evenly distribute the extract over the hide or skin. This process takes about three to four days and produces a leather that is flexible and is often used for furniture or luggage.

Mineral Tanning

This process involves the use of a chemical called chromium sulfate which has to soak sufficiently into the animal hide or skin to achieve proper tanning.

This process takes around twenty-four hours to complete and produces a leather that is stretchable, which is great for handbags and apparel.

Drying the Leather

After the hides or skins have gone through the tanning process, they can be considered a leather. Hang the leather out to dry over rods in a cool, semi-moist area. Using a fan to help speed up the drying process is possible but leather ought to best be dried slowly in a gradual manner.

Should the leather not be drying evenly, using some damp rags to re-moisten the areas that are drying faster is a good idea.

Soften the Leather

A machine called a staker can soften the leather by stretching it and lubricating it with natural oils. This process ensures the leather stays pliable.

An alternative is to also hang the hide or skin from the ceiling and stretch it as much as possible in different directions. Ropes and hooks may also be used to keep the hide taut.

Softening Oil Application

When the leather is eighty percent dry an oil application is used on the surface. It is important to even the application out on the surface. This process can be repeated several times through the drying process.

Smoke the Hide

The hide or skin is soft and pliable but depending on the purpose of the product, you may want to smoke the hide to force the tannin into the fibers. Stitch the hide or skin to form a bag and suspend the opening above a small smoky fire for several hours.

Using different types of wood can even add a natural color to the leather. Aspen or cottonwood can create golden leather. Try different wood types from your area to see what different colors and looks can be created.

Applying a Finish

By now the leather is buffed and polished though you might want to choose to treat the leather further with a coat of acrylic or polyurethane to make patent leather or embossed leather respectively. Making and processing leather is a complicated task that requires expertise. That in the end gives the desired leather finishing.

FAQs

From crocodiles to sheep and goats, leather can be made from almost any animal, though the most commonly used raw material would be cows.

Leather is produced in Argentina, USA, Russia, Italy, South Korea, Brazil, India, China, Japan and Pakistan.

Yes, genuine leather is made from animals, specifically cow-hide, goat, buffalo and exotic leathers such as alligator and snake.

Leather is used in several different ways for binding, clothing, furniture, footwear, saddles, gloves, watches, sports, bags, cases, holsters, and upholstery.

Conclusion

Concluding such an informative and complex subject may not be as simple as it sounds, yet; it is important to remember that the backbone of how is leather made involves prepping, salting, soaking, hair removal, and a final bath, without which this vital process would be incomplete. After this, as well as the drying of the leather, a particular tanning process is implemented that is selected from vegetable tanning, mineral tanning, or brain tanning, depending on what the requirements are. Some more drying time for the leather after tanning leads to the softening and smoking of the leather. This leads to the application of a finish that seals in all the previous treatments and processes. So that will lead to wap up and the processes carried out in order to get you to know all about leather.