Latigo leather is mainly produced out of cowhide, which uses 2 tanning processes respectively. The initial one is chrome tanning-which involves chromium sulfate and chromium salts, and vegetable tanning which involves plant-based ingredients and products. Latigo leather is not well-known because of its unbelievably high prices.

What To Expect In This Article?

The Origin

Latigo is the Spanish word for ‘whip’ for which the leather was used initially. Latigo leather is mainly known for its durability, which comes from both tanning processes, the flexibility and the beautiful leather patina it gets with time.

How It Is Made?

Produced primarily from the sturdy cowhide leather, latigo leather is made from the 2 tanning processes, chrome-tanning and vegetable tanning respectively, it is then drum dried and soaked into hot oils. The better the process the better the outcome. Latigo leather gets its durability because of the oils that are induced in it.

Let’s take a deep look at how the steps work;

Chrome Tan

The hide is first tanned using chromium sulfate and chromium salts, most of the leather industry uses the chrome tanning process, approximately 90%+. The leather gets a softer and pliable nature as well as the leather isn’t vulnerable to discoloration or shrinkage like other types of leather.

Vegetable Tan

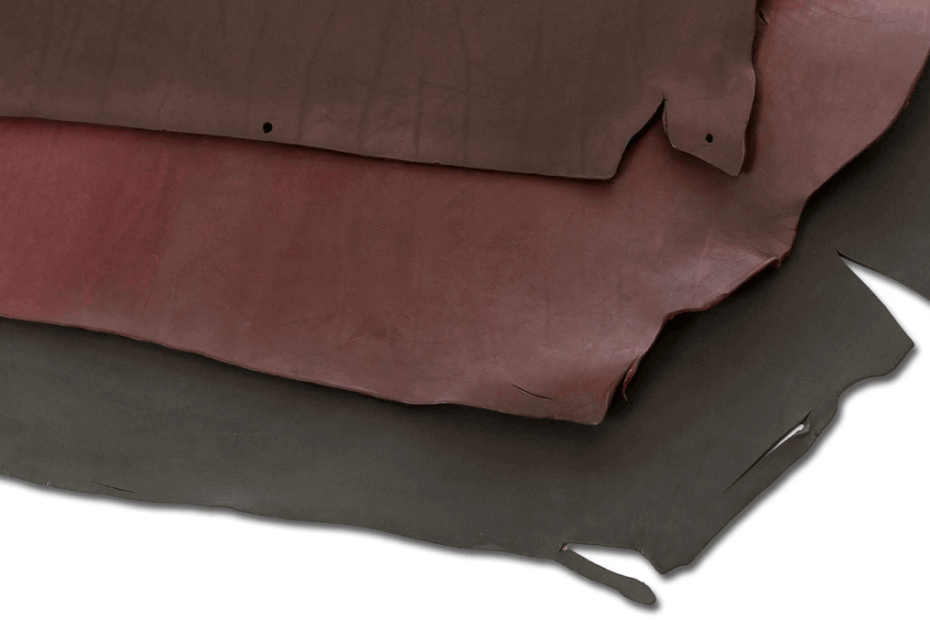

The leather is then re-tanned using plant-based ingredients. The process doesn’t involve chemicals. It is mainly an organic process that uses nature’s ingredients to sustain the leather. But vegetable tanned leather is highly vulnerable to water as it leads to discoloration and brittleness. The hide gets the brownish color originally when tanned through this very process.

Drum Drying

The hide is then drum dried using 2 drums. The hides are tumbled into a large drum to absorb the oils. This helps the leather retain its texture and color.

Fat Liquored

The hide is then nourished using various fats and oils. This helps with the appearance of Latigo leather.

Wet Stuffing

The hide is then introduced to emulsified oils or fats that add extra durability to the leather.

Hot Stuffing

The final process involves emulsified oils, wax, and fat. This adds pliability to the leather.

Quality

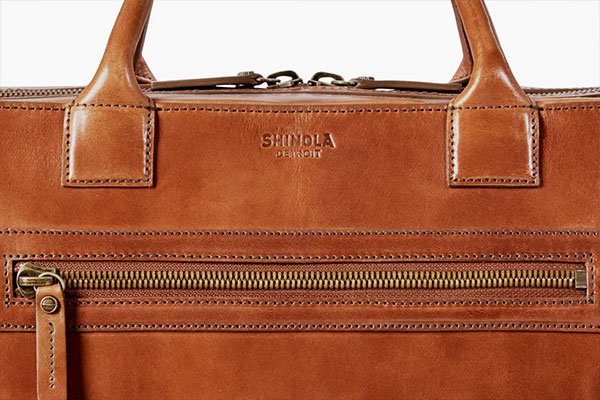

Latigo leather is known to be the heaviest leather when compared to the other types. With a static weight of 8-12 Oz, the weight gives it a durable nature that can be utilized for rough use easily. The leather can be made in a lighter weight depending upon the product that needs to be manufactured by it.

Appearance

Latigo leather was initially manufactured in the shades of burgundy but as of now, it is easily available in any color by going through the leather dying process. The leather is rigid yet soft when felt.

Advantages

As the leather is manufactured using oils that gives the leather a moisture blockage. This makes it somewhat water-resistant and tough. The overall durability of a Latigo cowhide is flawless in every way possible.

Disadvantages

The leather is not stamped/carve-friendly at all. As for its rigid-springy nature. It is also very heavy in weight compared to other leathers and the drastic difference compared to lightweight leather. This makes the leather very expensive as it also involves various processes and a couple of days to manufacture.

Latigo Leather Vs Bridle Leather

Bridle leather is also induced with various oils to retain its softer and luxurious feel, so is latigo leather. But the main difference between the two is, latigo leather is comparatively heavier and durable than bridle leather. Latigo uses 2 tanning processes, the bridle is only vegetable-tanned leather.

Latigo leather Vs Harness Leather

Harness leather is also durable and strong which makes it easier to retain the shape when sliced thin. The leather is vulnerable to sunlight as it makes it to discoloration. Both latigo and Harness are the same in a lot of ways except for the weight and water resistance. Latigo leather is highly capable of rough use.

F.A.Qs

What is Latigo leather used for?

Latigo leather is used to manufacture many products. But it is mainly used to produce products that are in constant use and require great durability like leather biker jackets, belts, straps, pet collars, riding tack, boots, and leather bags.

Is Latigo leather waterproof?

Yes! Latigo leather is highly waterproof except for the fact that it leaves impressions of the color, which can be fixed using a thin layer of beeswax.

What is horween Latigo leather?

Horween’s Latigo leather is a full-grain, vegetable tan leather. Characterized by pretty tight grain and made in a full range of color, finishes, weights, and tempers.

Is Latigo leather chrome-tanned?

Yes! Latigo leather is initially chrome-tanned using chromium sulfate and chromium salts.

Can Latigo leather be burnished?

Yes! The edges of latigo leather can be burnished due to the vegetable re-tanning process.

Conclusion

The leather is manufactured using two tanning processes; chrome tan and vegetable re-tan. The hide is then drum dried and soaked in hot oils which makes the leather nourish and durable. The leather ages well with having a beautiful patina over time. The latigo is used in various products which require rough use and water resistance.