The ongoing confusion of bespoke vs made-to-measure has rattled close to everyone surfing the internet, simply searching for easy ways to separate these two misunderstood concepts. While some sources offer great stories, others; many infographics that have complicated lingo, offer no help to people who aren’t ‘industry’ workers and so don’t quite know the terminology used.

In order to understand the differences of bespoke vs made-to-measure it is first important to recognize what each of these methods mean on their own and then in fashion terms so as to reach some memorable points that differentiate between the two.

What To Expect In This Article?

So What Is Bespoke and Made-to-Measure?

As the name suggests, bespoke; meaning to give order for it to be made, commissioned or arranged for, is a term used specifically for a tailored process that offers the highest form of customization that is as exclusive as the process itself.

The keywords here are exclusive, highest customization and commissioned which all point to one distinct factor which is that this is a hand-made process that changes every common or uncommon element of bespoke vs made-to-measure.

This is also reflected in the value and price-point of this bespoke process which we shall highlight towards the ending of this post.

Made-to-measure would be the machine-made process that forms a contrast to bespoke in more ways than one. Unlike bespoke, made-to-measure traditionally has two different types that are full made-to-measure and half made-to-measure.

Full Made-To-Measure

Simply put, the defining element of this type of made to measure begins from the pattern making stage where the pattern is measured inch to inch of the person based also on posture. This is done for accuracy, fit and balance.

There are four balance issues to be dealt with here, two of which are really important. One being a vertical balance which is the relationship of the front and back from the shoulders downwards. The second important one being a horizontal balance, which is a relation between the front and back based on circumference.

The two minor ones are based on the relation between left and right as well as the angle of the shoulders for e.g. regular, square or sloped. Without these points, the process cannot be considered as full made-to-measure.

Even if the other elements such as construction and design elements as well as choice of fabric is found present.

Half Made-To-Measure

This calls for a similar undertaking as the previous point but in a reduced manner. Whether dealing with vertical and horizontal balance, construction and design elements or the choice of fabric.

Pattern making especially based on posture is greatly reduced in terms of detail as mentioned above. Constructing the actual product as well as incorporating design elements are also greatly reduced to a minimum or very basic module.

While full made-to-measure allows some freedom to edit design options, half made-to-measure has a restriction to this set of points.

What Does Bespoke Mean In Fashion?

While all of the defining factors of bespoke remain the same in a fashion context, the term bespoke refers to anything that is NOT off-the-rack i.e. from any type of store having ready-to-wear or even made-to-measure facilities.

A bespoke fashion piece is an individually or custom-made piece that is made from scratch for a particular individual.

Benefits Of Bespoke

Here’s five great benefits that have even inspired many to go for bespoke across the world.

- Best Fitting

- High Quality Materials

- Complements your Personal Style

- Minimum Time and Effort Used

- Lasts Longer than other Products

Benefits Of Made-To-Measure

- Looks Good

- Styled to Suit you

- Economical

- Exclusive Product

- Economical Quality

Drawbacks Of Bespoke

While many people may not be able to visualize drawbacks to bespoke, simply on the basis of it being the only option for achieving the perfect cut, fit and finish not to forget the incredibly high quality fabric and details that are used, would be surprised to know that this customized feature does have its share of drawbacks after all.

These drawbacks would be availability, convenience and cost. Let’s take a step or two in detail shall we? Just as bespoke may have many advantages to its favor, it may not be as widely available especially in places where tailors are rather scarce.

Or if there are tailors around they may not all do bespoke for reasons that are linked to our second drawback which is convenience. Bespoke garments take twice or more time to make than any other type of garment.

This is due to it being closely measured and made that requires both time and patience. It can take roughly three weeks or more to have a bespoke garment made.

This tells us that not only does bespoke require a good deal of searching, it also calls for time and patience for a perfectly crafted bespoke piece to be achieved. Of-course with all this availability and convenience comes a price which is the cost of a bespoke piece and truth be told it’s no tiny chunk of change.

Drawbacks Of Made-To-Measure

The only drawback of made-to-measure products is the limitations that arise in the form of limited materials, limited to no customization and detailing, time consumption and alterations made roughly to fit the person are a few downsides to this process.

While many may look at the advantages in that it is more economical and somewhat exclusive, do not justify the drawbacks for it to be chosen over bespoke and what that process has to offer.

Modern day technology is being used to redefine made-to-measure which is probably another reason why the gap between bespoke vs made-to-measure has grown relatively thin, adding to the confusion between people as to which is which.

Whether through 3d scanners that help in achieving reliable and quick measurements to pre-programmed patterns as well as 3d and 2d simulations that help in accomplishing measure, color, design and texture of fabrics for each individual.

While this computerized medium may seem like a blessing in disguise it may instead grow to mimic bespoke which in turn will further confuse many as never before.

Six Steps To Distinguish Between Bespoke vs Made-To-Measure

The five steps mentioned below that distinguish between bespoke vs made-to-measure may underline common factors between the two processes yet are to be treated as different as they each have dissimilar approaches that make them both unique.

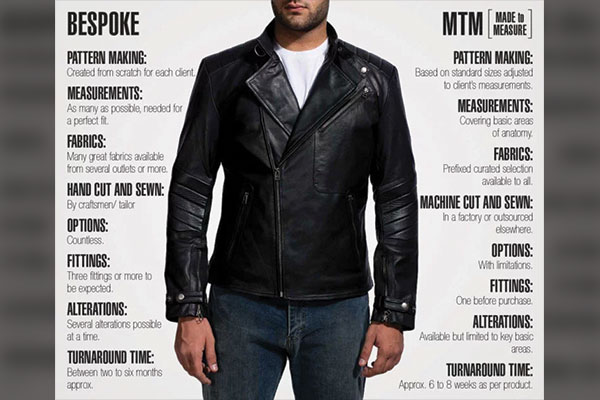

- Pattern Making

Pattern making is the first stage you will notice when going for bespoke. While for bespoke, a pattern is drafted from scratch based on centimeter by centimeter measurements of the individual including every curve, line or dip that is formed in the process, resulting in a perfect fit.

Which is a sharp contrast to the pattern made for a made-to-measure order which is carried out on an already existing pattern, or one that is tweaked as per person. This is often a standard or general set of measures based on an average person.

If we were to go by bespoke vs made-to-measure, we’d find that a made-to-measure product may fit well in an ideal scenario, yet a bespoke product will always fit perfectly…like a glove!

Another interesting and valid point regarding pattern making and bespoke is that every single change, addition or removal from the pattern made, is allowed and executed accordingly, whereas for made-to-measure there is no such option. The altered product is presented to the individual with no further changes entertained.

- Fabric Selection

As with pattern making, bespoke vs made-to-measure have another common factor, which is fabric selection which again, as with pattern making, bespoke allows for unlimited options and possibilities whereas made-to-measure offers one limited range that is curated for all.

These points gel well with color selection as well as design customization which we shall cover next.

- Design Customization

When we talk about bespoke vs made-to-measure and design customization, we refer to all design elements that are used within the product that is either edited or added as per individual requirement.

While bespoke offers an open field for edits, additions, subtractions, details and even adornments, made-to-measure draws a line at what is possible and what is not.

Made-to-measure design customization may allow you to choose the number of buttons, pockets, cuffs etc. used within the product but nothing more.

Bespoke allows you to incorporate anything you’d like from physical features to details and adornments. The same goes for color which moves simultaneously with design as well as fabric selection.

- Made-In-House

This is an important point and a fact that creates an evident divide between bespoke vs made-to-measure. While all bespoke products are made in house from start to finish.

Including all stops and turns of the process to be handled and managed within one place, makes this one of the defining points that separates the two processes.

Made-to-measure however, is often found to involve quite a lot of outsourcing as time is of the essence in a factory themed process and environment. Hence this point would be a defining factor of bespoke vs made-to-measure.

- Multiple Fittings

This especially applies to shirts and suits. Multiple fittings are required for a bespoke product to achieve its status of perfection.

A number that varies from product to product based on type and style. Typically a bespoke suit would require three fittings before it reaches the final stage.

However made-to-measure products only require one instead of three or more. Often the person can pick-up the product after the first fitting. This makes for another identifying factor of bespoke vs made-to-measure.

- Cost

Last yet definitely not least is the element that takes into account all the time that is spent on the product, craftsmen used, changes, edits and more.

Bespoke would understandably have much of this reflected in the cost which is much higher than made-to-measure.

While a made-to-measure product such as a suit, may have an $800 price tag; a bespoke suit would undoubtedly carry a $2600 price tag. This is where our bespoke vs made-to-measure evaluation reaches the ultimate of all defining points.

Winding-up this Post

After reading the above, and despite popular beliefs; we now know that there is a significant difference between bespoke and made-to-measure. While both models may offer exclusivity by fluctuating degrees, bespoke wins by offering unlimited options.

The same applies for sizing, fabric choice and time-frame. However, as with all things, both bespoke and made-to-measure do have a down-side as well, this would be regarding availability, investment of time and money, a big one for bespoke and most of all may even be a big inconvenience for people.

Ultimately, it’s all about personal choice and function and choosing one over the other would be determined on the purpose and place the product will serve.